CONTAINER & ORDER MANAGEMENT FOR A NEW ERA OF SUPPLY CHAIN

The importance of the supply chain is now clear to all, but will your technology meet the expectation

GLOBAL CONTAINER AND ORDER MANAGEMENT

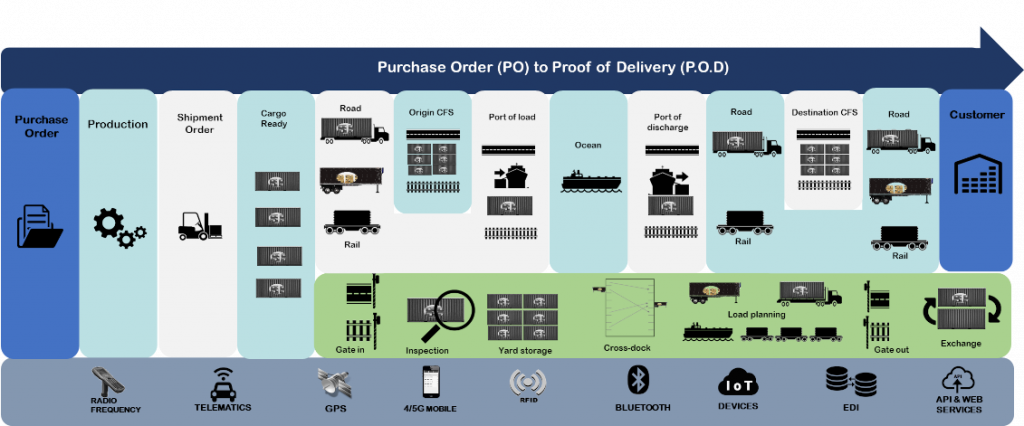

Accurate container and order visibility and control has long been the ultimate goal for manufacturers (OEMs) and lead logistics providers (LLPs), however the software solutions market has never really embraced or facilitated this goal, preferring to focus solely on individual segments or modes thereby further perpetuating the antiquated, silo’d approach to supply chain management.

This partly because container management can mean many things to many people as do container management software solutions. Whereas service providers may be interested in little more than the container itself and its cargo classification, the shipper of that cargo will be interested in far more detailed information about the cargo including shipment order information, purchase order, packaging media and SKU level information.

Knowing which SKUs are in which containers, which order lines they represent and which purchase order they reconcile against can be critical to the shipper. In addition, knowing where the container is destined, how it will be routed there and what are the latest ETAs at each point in the supply chain and ultimately its final ETA it critical. This is especially true if the cargo is feeding local manufacturing plant or fulfilling the needs of time critical or seasonal sales channels. Having visibility and control of all of this information seamlessly, end-to-end visibility within one solution, ProAct calls a ‘Control Tower’.

A true Control Tower technology brings many benefits, not least that it can project more accurately, down to SKU level the availability of product currently in the supply chain at its final destination. Knowing what product is in which containers at what points in the supply chain also makes it easier to re-prioritise individual containers and expedite critical SKUs. All of this relies on the solution capable of having a detailed understanding of the entire process flow, its decision logic, its dependencies, its service providers, its constraints and overall the routing options for a specific container. This in turn relies on a technology that is dynamic, configurable and flexible enough to project, predict and optimise a complex end-to-end, multi-modal supply chain based on all of this data.

HIGH LEVEL SOLUTION SCOPE

Multi-Language/Terminology

Multi-Time Zone

Multi-Yard/Site/Location

Multi-Currency

Multi-Unit Of Measures (UOM)

Multi-Modal (Transport)

VIN Decoding

Factory-to-consumer planning and execution

End-to-end control tower visibility

Aftermarket VIN activity management

Network Yard Management

Yard Graphical real-time visualization

Multi-modal route and process planning

Dynamic multi-modal Itinerary projection

Sophisticated yard process/activity management

Perpetually configurable events & triggers

Service provider allocation and collaboration

Route capacity constraints

Resource capacity constraints

UMLER data storage and reference facility

Document Management (including barcode, QR code creation)

Workshop, Resource & Parts Control and Planning

Truck, Railcar and Vessel Load/Manifest Planning & Tracking

KPI Tracking & MIS dashboarding

Vehicle or Equipment photographic inspections & surveys

‘Hold’ management & release

AIAG format damage management

Upfitting management (PIO,DIO,FIO)

Equipment management

Cost And revenue tariff management

Freight Audit Billing management

Extensive Integration capabilities (EDI, Web Services, APIs, GPS etc)

Resource capacity constraints

Rail Load Management

Barcode Scanning

RFID Configuration

Storage management

TELEMATICS

VIN originating data capture/request

Status recording (battery, tyre, GPS etc)

Status based rules and task triggers

Automatic assignment of yard tasks

Resolution verification

MOBILE DEVICE SUPPORT

Android native online/offline App Secure device authorisation

Inspection/Survey Management

Automatic Job allocation & management

Photo, annotation and signature capture

GPS tracking & Geofencing

Range of operational support functions

NOT ALL YARD MANAGEMENT SOLUTIONS ARE BUILT THIS WAY

Over the years ProAct has deployed yard management solutions on behalf of a number global 3PL providers. Today we consider both our yard management solution and wider finished vehicle logistics solutions to be unique and differentiating ‘best of breed’ global capabilities. The summary below only touches on the extensive scope and depth of capabilities available within this solution.

From the ProAct solutions user community…

Downtime related to software has not been seen by our organization. We have the utmost confidence in this product to maintain our customer needs.

The emphasis on making the software user-friendly recognizes the need for the end-users to be able to use the tool and do their specific jobs.

I like the possibilities of the software growing with our needs as we address expanding pieces of the market.

I like the deep industry knowledge of the team that supports us, which continue to grow over time.

Find out how ProAct could help your organisation

For an initial, no-obligation consultation simply complete the form below and we’ll get right back to you.